Most Powerful Permanent Magnets - Neodymium Magnets

NdFeB magnet (also known as Neo, NdFeB, or NIB magnet) is a permanent magnet material based on the Nd-Fe-B tetragonal structure. Sintered NdFeB magnets contain three basic elements of neodymium, iron, and boron, which are manufactured by powder metallurgy process.

Neodymium magnet is a new type of magnetic material with excellent magnetic properties and competitive cost. Sintered NdFeB magnets are widely used in DC motors, servo motors, stepping motors, voice coil motors (VCM), wind turbines, etc.

XHMAG Has been a leading supplier of high-quality sintered NdFeB magnets. We offer the most competitive prices in the industry along with in-house quality control and on-time delivery services.

Custom Neodymium Magnets for Your Project

XHMAG has expertise in the technical design, engineering, manufacturing, assembly, and testing of custom neodymium magnets and precision magnetic assemblies.

We often provide services for industrial motor manufacturers, wind turbine generator manufacturers, permanent magnet drive motor manufacturers, sensor manufacturers, speaker manufacturers, magnetic hand tool manufacturers, and foreign magnet trading companies.

No matter what type of neodymium magnet you need, we can provide it for you. Send us a request for a quote or contact us today to discuss the professional requirements of your project.

Neodymium Magnet Shape

Grades of Neodymium Magnets

| Grade | Remanence(BR) | Coercivity(Hcb) | Instrinsic Coercivity(Hcj) | Max Energy Product | Max Working temperature | ||||

| K Gauss | mT | K Oe | KA/m | K Oe | KA/m | MGOe | Kj/m³ | ℃ | |

| ND-30 | 10.80-11.30 | 1080-1130 | ≥10.00 | ≥796 | ≥12.00 | ≥955 | 28~31 | 233~247 | <80℃ |

| ND-33 | 11.30-11.70 | 1130-1170 | ≥10.50 | ≥836 | ≥12.00 | ≥955 | 31~34 | 247~271 | <80℃ |

| ND-35 | 11.70-12.20 | 1170-1220 | ≥10.90 | ≥868 | ≥12.00 | ≥955 | 33~36 | 263~287 | <80℃ |

| ND-38 | 12.20-12.50 | 1220-1250 | ≥11.30 | ≥899 | ≥12.00 | ≥955 | 36~39 | 287~310 | <80℃ |

| ND-40 | 12.50-12.80 | 1250-1280 | ≥11.40 | ≥907 | ≥12.00 | ≥955 | 38~41 | 302~326 | <80℃ |

| ND-42 | 12.80-13.20 | 1280-1320 | ≥11.50 | ≥915 | ≥12.00 | ≥955 | 40~43 | 318~340 | <80℃ |

| ND-45 | 13.20-13.80 | 1320-1380 | ≥11.60 | ≥876 | ≥12.00 | ≥955 | 43~46 | 342~366 | <80℃ |

| ND-48 | 13.80-14.20 | 1380-1420 | ≥11.60 | ≥836 | ≥12.00 | ≥955 | 46~49 | 366~390 | <80℃ |

| ND-50 | 14.00-14.50 | 1400-1450 | ≥10.00 | ≥796 | ≥11.00 | ≥876 | 48~51 | 382~406 | <80℃ |

| ND-52 | 14.30-14.80 | 1430-1480 | ≥10.00 | ≥796 | ≥11.00 | ≥876 | 50~53 | 398~422 | <80℃ |

| ND-30M | 10.80-11.30 | 1080-1130 | ≥10.00 | ≥796 | ≥14.00 | ≥1114 | 28~31 | 233~247 | <100℃ |

| ND-33M | 11.30-11.70 | 1130-1170 | ≥10.50 | ≥836 | ≥14.00 | ≥1114 | 31~34 | 247~271 | <100℃ |

| ND-35M | 11.70-12.20 | 1170-1220 | ≥10.90 | ≥868 | ≥14.00 | ≥1114 | 33~36 | 263~287 | <100℃ |

| ND-38M | 12.20-12.50 | 1220-1250 | ≥11.30 | ≥899 | ≥14.00 | ≥1114 | 36~39 | 287~310 | <100℃ |

| ND-40M | 12.50-12.80 | 1250-1280 | ≥11.60 | ≥923 | ≥14.00 | ≥1114 | 38~41 | 302~326 | <100℃ |

| ND-42M | 12.80-13.20 | 1280-1320 | ≥12.00 | ≥955 | ≥14.00 | ≥1114 | 40~43 | 318~340 | <100℃ |

| ND-45M | 13.20-13.80 | 1320-1380 | ≥12.50 | ≥955 | ≥14.00 | ≥1114 | 43~46 | 342~366 | <100℃ |

| ND-48M | 13.80-14.20 | 1380-1420 | ≥12.90 | ≥1027 | ≥14.00 | ≥1114 | 46~49 | 366~390 | <100℃ |

| ND-50M | 14.00-14.50 | 1400-1450 | ≥13.00 | ≥1027 | ≥14.00 | ≥1114 | 48~51 | 382~406 | <100℃ |

| ND-30H | 10.80-11.30 | 1080-1130 | ≥10.00 | ≥796 | ≥17.00 | ≥1353 | 28~31 | 233~247 | <120℃ |

| ND-33H | 11.30-11.70 | 1130-1170 | ≥10.50 | ≥836 | ≥17.00 | ≥1353 | 31~34 | 247~271 | <120℃ |

| ND-35H | 11.70-12.20 | 1170-1220 | ≥10.90 | ≥868 | ≥17.00 | ≥1353 | 33~36 | 263~287 | <120℃ |

| ND-38H | 12.20-12.50 | 1220-1250 | ≥11.30 | ≥899 | ≥17.00 | ≥1353 | 36~39 | 287~310 | <120℃ |

| ND-40H | 12.50-12.80 | 1250-1280 | ≥11.60 | ≥923 | ≥17.00 | ≥1353 | 38~41 | 302~326 | <120℃ |

| ND-42H | 12.80-13.20 | 1280-1320 | ≥12.00 | ≥923 | ≥17.00 | ≥1353 | 40~43 | 318~340 | <120℃ |

| ND-45H | 13.00-13.60 | 1300-1360 | ≥12.10 | ≥963 | ≥17.00 | ≥1353 | 43~46 | 342~366 | <120℃ |

| ND-48H | 13.70-14.30 | 1370-1430 | ≥12.50 | ≥995 | ≥17.00 | ≥1353 | 46~49 | 366~390 | <120℃ |

| ND-30SH | 10.80-11.30 | 1080-1130 | ≥10.10 | ≥804 | ≥20.00 | ≥1592 | 28~31 | 233~247 | <150℃ |

| ND-33SH | 11.30-11.70 | 1130-1170 | ≥10.60 | ≥844 | ≥20.00 | ≥1592 | 31~34 | 247~271 | <150℃ |

| ND-35SH | 11.70-12.20 | 1170-1220 | ≥11.00 | ≥876 | ≥20.00 | ≥1592 | 33~36 | 263~287 | <150℃ |

| ND-38SH | 12.20-12.50 | 1220-1250 | ≥11.40 | ≥907 | ≥20.00 | ≥1592 | 36~39 | 287~310 | <150℃ |

| ND-40SH | 12.50-12.80 | 1250-1280 | ≥11.80 | ≥939 | ≥20.00 | ≥1592 | 38~41 | 302~326 | <150℃ |

| ND-42SH | 12.80-13.20 | 1280-1320 | ≥12.40 | ≥987 | ≥20.00 | ≥1592 | 40~43 | 318~340 | <150℃ |

| ND-45SH | 13.20-13.80 | 1320-1380 | ≥12.60 | ≥1003 | ≥20.00 | ≥1592 | 43~46 | 342~366 | <180℃ |

| ND-28UH | 10.20-10.80 | 1020-1080 | ≥9.60 | ≥764 | ≥25.00 | ≥1990 | 26~29 | 207~231 | <180℃ |

| ND-30UH | 10.80-11.30 | 1080-1130 | ≥10.20 | ≥812 | ≥25.00 | ≥1990 | 28~31 | 233~247 | <180℃ |

| ND-33UH | 11.30-11.70 | 1130-1170 | ≥10.70 | ≥852 | ≥25.00 | ≥1990 | 31~34 | 247~271 | <180℃ |

| ND-35UH | 11.80-12.20 | 1180-1220 | ≥10.80 | ≥860 | ≥25.00 | ≥1990 | 33~36 | 263~287 | <180℃ |

| ND-38UH | 12.20-12.50 | 1220-1250 | ≥11.00 | ≥876 | ≥25.00 | ≥1990 | 36~39 | 287~310 | <180℃ |

| ND-40UH | 12.50-12.80 | 1250-1280 | ≥11.30 | ≥899 | ≥25.00 | ≥1990 | 38~41 | 302~326 | <200℃ |

| ND-28EH | 10.40-10.90 | 1040-1090 | ≥9.80 | ≥780 | ≥30.00 | ≥2388 | 26~29 | 207~231 | <200℃ |

| ND-30EH | 10.80-11.30 | 1080-1130 | ≥10.20 | ≥812 | ≥30.00 | ≥2388 | 28~31 | 233~247 | <200℃ |

| ND-33EH | 11.30-11.70 | 1130-1170 | ≥10.50 | ≥836 | ≥30.00 | ≥2388 | 31~34 | 247~271 | <200℃ |

| ND-35EH | 11.70-12.20 | 1170-1220 | ≥11.00 | ≥876 | ≥30.00 | ≥2388 | 33~36 | 263~287 | <200℃ |

| ND-38EH | 12.20-12.50 | 1220-1250 | ≥11.30 | ≥899 | ≥30.00 | ≥2388 | 36~39 | 287~310 | <200℃ |

Coating of Neodymium Magnets

| Coating | Thickness (μm) | SST (hr) | PCT (hr) | Tw (ºC) |

| Zn (Zinc) | 45061 | >24 | - | ≤160 |

| C-Zn (Colored Zinc) | 45061 | >48 | - | ≤160 |

| Electroless Nickel | 45229 | >96 | >72 | ≤230 |

| NiCuNi (Nickel Copper Nickel) | 45219 | >48 | >48 | ≤230 |

| NiCu + Black Nickel | 45219 | >48 | >72 | ≤230 |

| NiCuNi + Tin | 45224 | >48 | >48 | ≤160 |

| NiCuNi + Gold | 45224 | >48 | >48 | ≤230 |

| NiCuNi + Silver | 45224 | >48 | >48 | ≤160 |

| Epoxy | 45229 | >72 | >48 | ≤160 |

| Teflon | 45219 | >48 | - | ≤230 |

| Everlube | 45219 | >96 | >72 | ≤230 |

| Parylene | 0.2-5 | >96 | - | ≤230 |

Physical Properties of Neodymium Magnets

| Physical Properties | |

| Temp Coeff of Br | -0.09-0.11%/℃ |

| Density | 7.45~7.7g/cm3 |

| Vickers Hardness | 600Hv |

| Tensile Strength | 8.0kg/mm2 |

| Specific Heat | 0.12KCAL/(kg,℃) |

| Youngs Ratio | 1.6x1011N/m2 |

| Poissons Ratio | 0.24 |

| Curie Temperature | 310-340℃ |

| Temp Coeff of Hc | -0.48-0.63%/℃ |

| Electrical Resistivity | 114 μ Ω cm |

| Flexural Strength | 25kg/mm |

| Hardness | 0.64N/m2 |

| Compressibility | 9.8*10-12 m2/N |

| Coeff of Thermal Expansion | 4*10-6 /℃ |

| Thermal Conductivity | 7.7kcal/(m.h.℃) |

| Relative Recoil Permeability | 1.05 |

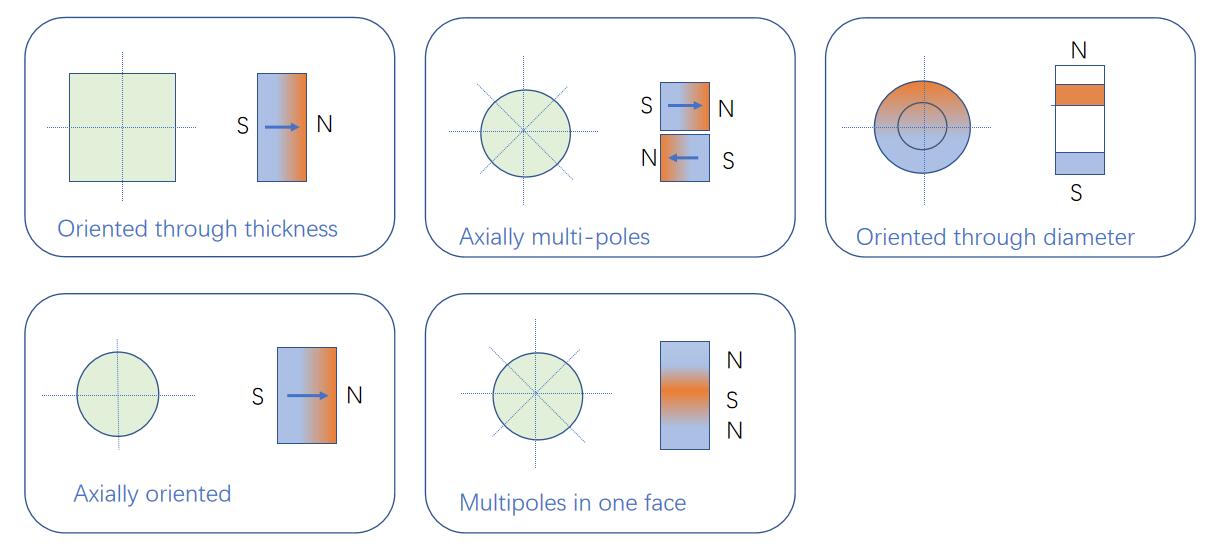

Neodymium Magnet Magnetization Direction

The Manufacturing Process of Neodymium Magnets

The manufacturing process of neodymium magnets includes 7 main steps: melting, grinding, pressing, sintering, machining, coating, magnetization.

What Are the Main Uses of Neodymium Magnets?

The main application fields of our neodymium magnets are wind energy, petroleum energy, automobile, electronic industry, IT, medical treatment, mining, audio-visual, sports, toys, stationery, printing, packaging, gift crafts, etc.

Hefei Xinhui Magnet Co.,ltd is a professional manufacturer of sintered neodymium magnets. We manufacture permanent rare earth sintered neodymium magnets with high quality and affordable price, and help you choose the right magnet for your application, just click Send Email.